The materials science landscape is undergoing a remarkable transformation as researchers and engineers continue Weaving the Future: Exploring the frontiers of advanced composites with unprecedented innovation. These sophisticated materials represent the culmination of decades of scientific advancement, combining multiple constituent elements to create substances with properties far superior to their individual components. From aerospace applications to everyday consumer products, advanced composites are revolutionizing how we build, travel, and interact with our world.

The evolution of composite technology

Composites have existed in rudimentary forms for thousands of years. Ancient civilizations combined straw and mud to create stronger building materials, unwittingly pioneering concepts that would eventually lead to today’s high-performance composites. The modern era of composite development began in the mid-20th century, primarily driven by aerospace and defense requirements for materials that offered exceptional strength-to-weight ratios.

Today’s advanced composites bear little resemblance to these early iterations. Contemporary materials science has elevated composite technology to extraordinary levels of performance, developing materials that can withstand extreme temperatures, pressures, and environmental conditions while maintaining structural integrity. This progression has been particularly evident in sealing technologies, where specialized components like mica gasket material have transformed industrial capabilities.

Understanding the composition advantage

At their core, advanced composites combine two or more distinct materials to create a new substance with enhanced properties. The most common configuration involves a reinforcement material embedded within a matrix or binding material. This synergistic arrangement allows engineers to precisely calibrate performance characteristics based on specific application requirements.

The reinforcement typically provides strength and stiffness, while the matrix protects the reinforcement and transfers loads across the composite structure. This fundamental arrangement underlies countless composite variations, from carbon fiber reinforced polymers to ceramic matrix composites used in high-temperature applications. The expanding frontier of advanced composites continues to introduce new reinforcement and matrix combinations, pushing performance boundaries in virtually every industry.

Critical applications transforming industries

Aerospace remains at the forefront of advanced composite utilization. Modern aircraft incorporate composite materials throughout their structures, significantly reducing weight while maintaining or improving structural integrity. The Boeing 787 Dreamliner, for instance, features a structure that is approximately 50% composite materials by weight, enabling substantial fuel efficiency improvements and extended range capabilities.

Automotive engineering has similarly embraced Weaving the Future: Exploring the frontiers of advanced composites to address emissions and performance challenges. Formula 1 racing teams pioneered many composite applications that have since migrated to production vehicles. Carbon fiber reinforced polymers now appear in everything from high-performance sports cars to electric vehicle battery enclosures, offering weight reduction without compromising safety.

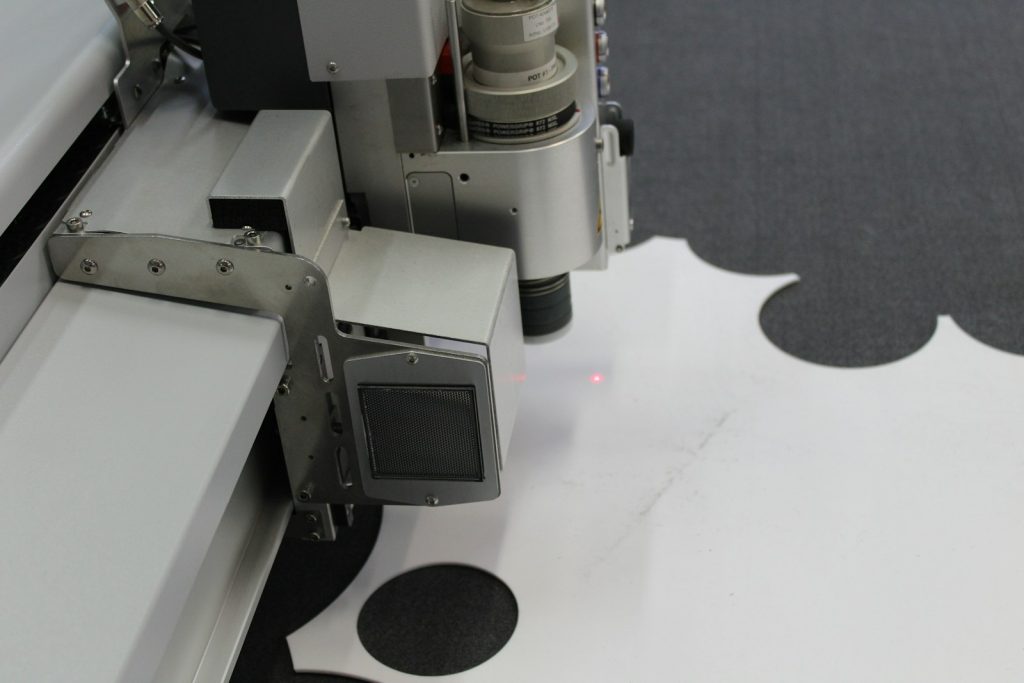

Industrial settings present some of the most demanding applications for advanced composites, particularly in sealing and containment systems. High-temperature environments require specialized materials like mica gasket material, which provides exceptional thermal resistance and electrical insulation properties. These sophisticated gaskets enable safe operation of equipment in extreme conditions where traditional sealing solutions would rapidly degrade.

Engineering challenges and innovative solutions

Despite their remarkable advantages, advanced composites present significant engineering challenges. Manufacturing processes often require precise control of conditions including temperature, pressure, and cure rates to achieve desired material properties. The anisotropic nature of many composites—exhibiting different properties depending on the direction of measurement—also necessitates sophisticated design approaches.

Joining composites to other materials presents additional complications. Traditional fastening methods can compromise composite integrity by introducing stress concentrations. This has spurred development of advanced adhesive technologies and innovative fastening systems specifically designed for composite applications. Metal gaskets with composite elements represent one solution to the joining challenge, providing effective sealing between dissimilar materials in critical applications.

Recyclability remains another frontier in composite development. The very characteristics that make many composites exceptional performers—their cross-linked polymer structures and intimately bonded constituent materials—can make them difficult to recycle. Researchers are actively developing new matrix materials that maintain performance while allowing for easier end-of-life processing and material recovery.

The future landscape of composite innovation

As we continue Weaving the Future: Exploring the frontiers of advanced composites, several promising directions are emerging. Multifunctional composites that simultaneously provide structural support while performing additional functions like energy storage, sensing, or self-healing represent one exciting frontier. Imagine aircraft wings that store electrical energy while maintaining their aerodynamic profile, or building materials that can detect and repair damage autonomously.

Nanomaterial reinforcements are revolutionizing composite performance. Carbon nanotubes and graphene, with their exceptional mechanical and electrical properties, can dramatically enhance composite strength, conductivity, and functionality when properly incorporated into matrix materials. These nanoscale reinforcements enable engineers to design at the molecular level, tailoring material behavior with unprecedented precision.

Biomimicry—drawing inspiration from natural structures—is providing new approaches to composite design. Nature has spent billions of years evolving elegant composite solutions like bone, shell, and wood. Scientists are decoding these natural composites to understand how relatively simple constituent materials can be arranged in sophisticated architectures to achieve remarkable performance. This bio-inspired approach is yielding new designs for everything from impact-resistant structures to lightweight, high-strength components.

The industrial sealing sector continues to benefit from these advances, with next-generation metal gaskets incorporating composite elements to address the most challenging containment scenarios. These hybrid solutions leverage the best properties of both metallic and composite materials, such as mica gasket material, providing reliable sealing in applications where traditional approaches fall short.

Have you considered how advanced composites might already be affecting your daily life? From the smartphone in your pocket to the building you work in, these materials are increasingly prevalent, often operating invisibly but essential to modern performance standards. As material science continues advancing, the integration of sophisticated composites into our infrastructure and products will only accelerate, bringing improved efficiency, sustainability, and capabilities to countless applications.